Digital Twin

Our Digital Twin solution revolutionizes the flow of goods in your warehouse. By leveraging existing inventory data and advanced simulation models, the system enables real-time simulation of various scenarios. This provides you with a solid decision-making foundation to optimize processes and achieve maximum efficiency. Every component of the solution works seamlessly together to make your warehouse operations smarter and more powerful.

- 9Bottleneck Detection

- 9Scenario Simulation

- 9Smart Slotting

- 9Adaptive to Demand

- 9Real-Time Staffing

- 9On-Time Fulfillment

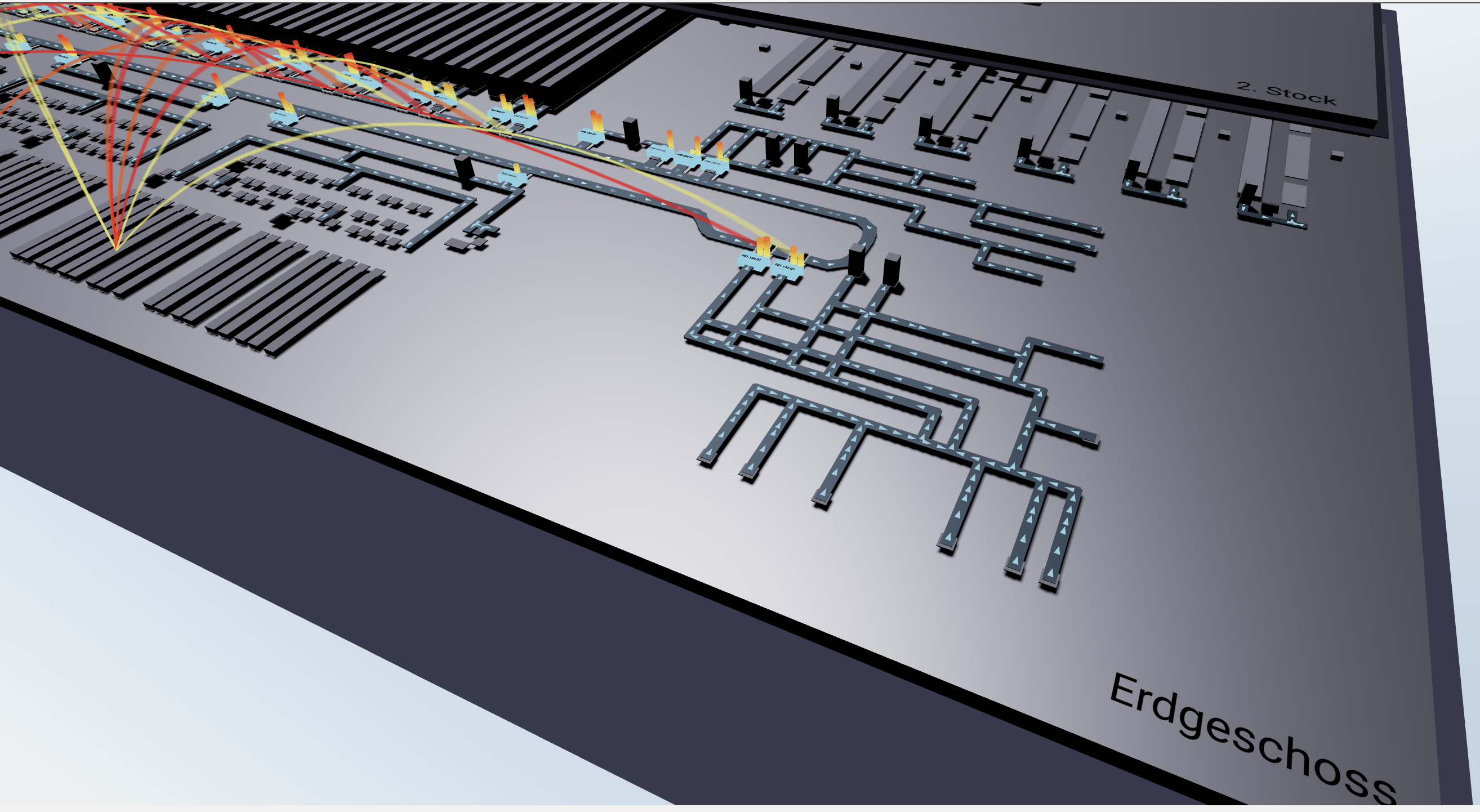

Supply Chain Simulation

Our simulation-based warehouse overview allows you to detect bottlenecks and potential problem areas early on. By simulating real processes, the system visualizes potential constraints and areas for improvement before they become actual issues. This enables you to take proactive measures and streamline the flow of goods efficiently.

Intelligent Slotting

Our intelligent slotting feature ensures optimal placement of goods within your warehouse. Using data-driven analysis and smart algorithms, each item is strategically positioned to support efficient material flow. This minimizes retrieval times, accelerates picking processes, and maximizes warehouse capacity utilization. The feature dynamically adapts to changing order patterns, ensuring efficient warehouse organization at all times.

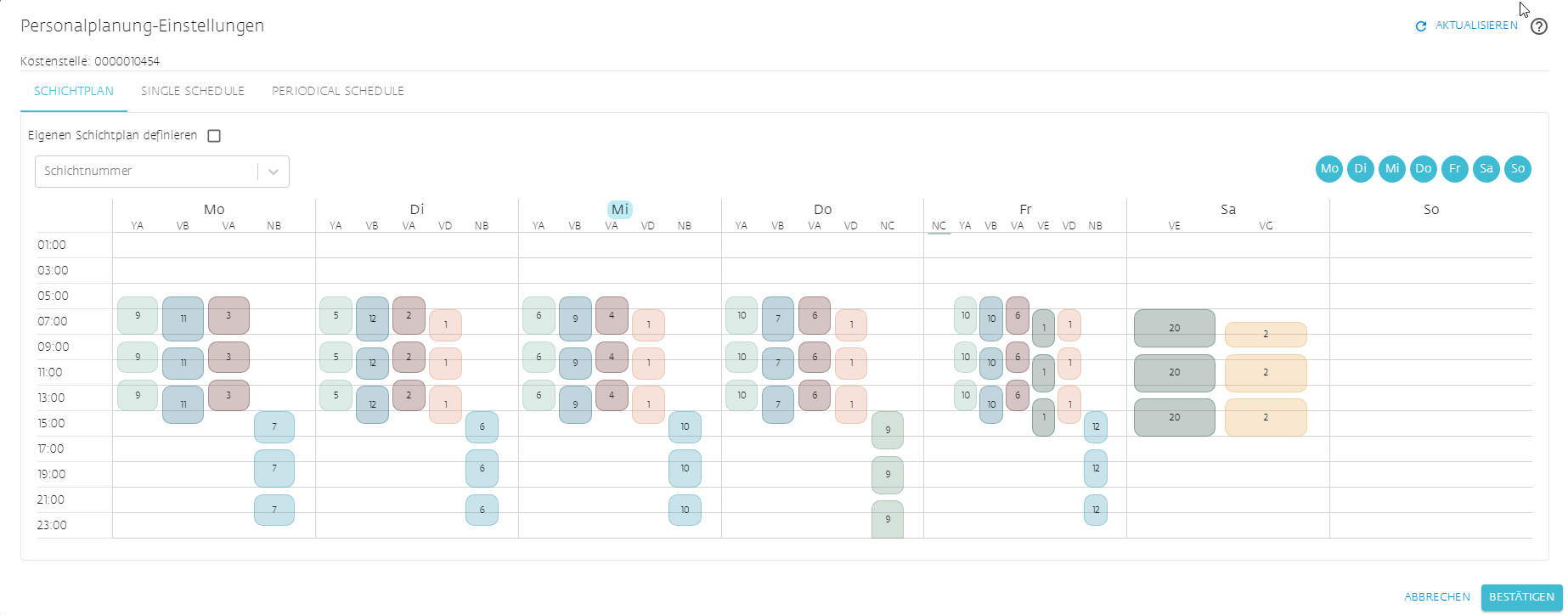

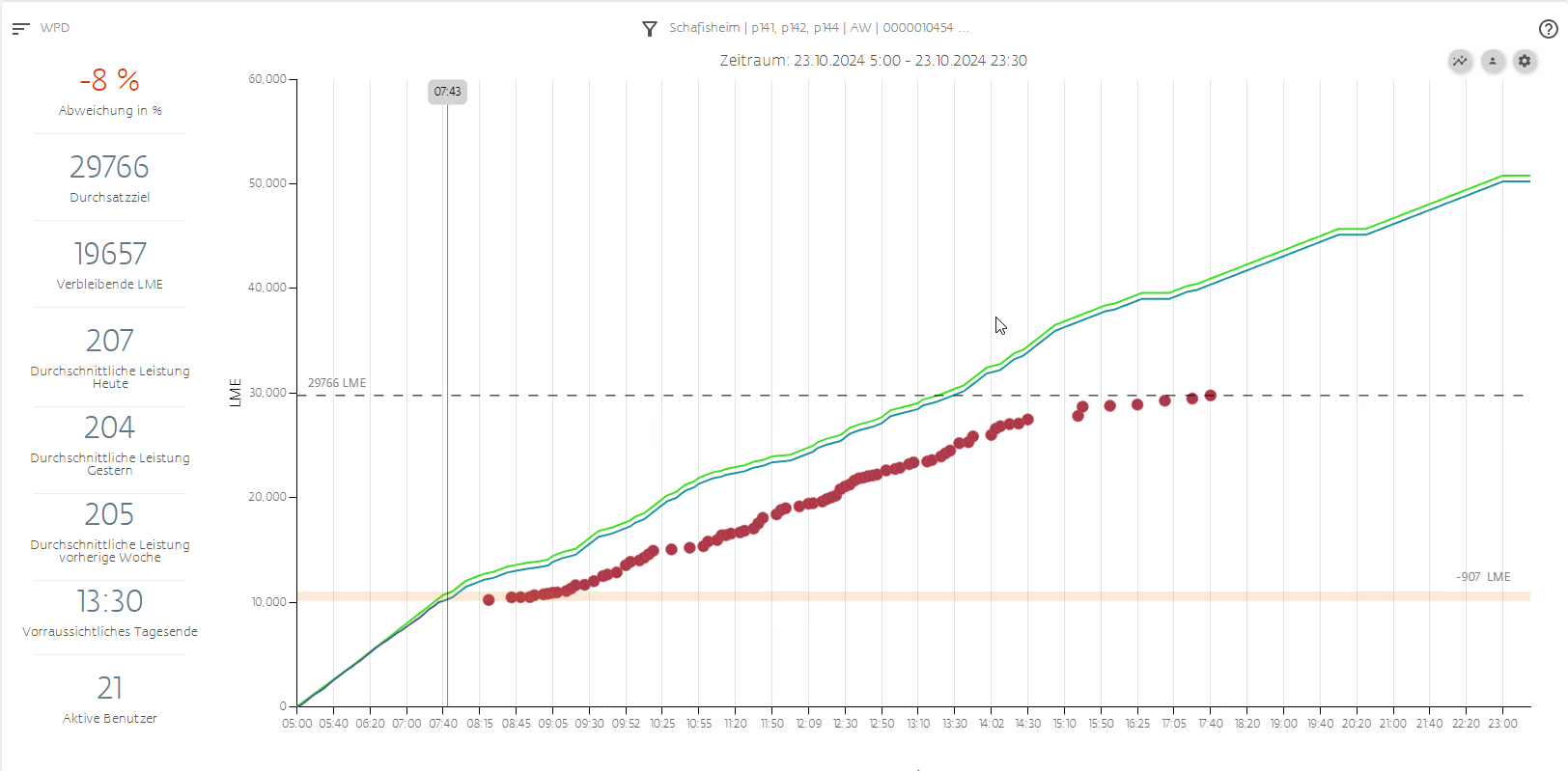

Real-Time Monitoring and Personnel Planning

With our Real-Time Monitoring, you can accurately plan workforce requirements in your warehouse.

This feature simulates workflows in specific warehouse areas in real time, helping you allocate personnel resources optimally. This ensures that departure and picking schedules are reliably met, preventing bottlenecks or overcapacity.